High-quality dies and tools for stamping applications.

The company was formed in 2016 after Bilsing Automation GmbH, a 40-year-old company with experience in supplying modular tooling for gripping and transporting to the automotive stamping and bodyshop, purchased an Iserlohn, Germany tooling shop with a 12-year history, mostly serving customers in Germany, Switzerland and Austria.

In 2018, Bilsing Werkzeugbau moved to a new Iserlohn facility, providing the company 1000m2 additional production space and 250m2 office space. Since then, the company has grow by 20% from 2019. There were 16 employees in 2020.

With its heritage, Bilsing Werkzeugbau is experienced, innovative and a quality-oriented partner for companies needing blanking, progressive, step and transfer tools for a variety of automotive applications. We have successfully developed complex press tools with up to 8 stages inclusive of heat shielding application.

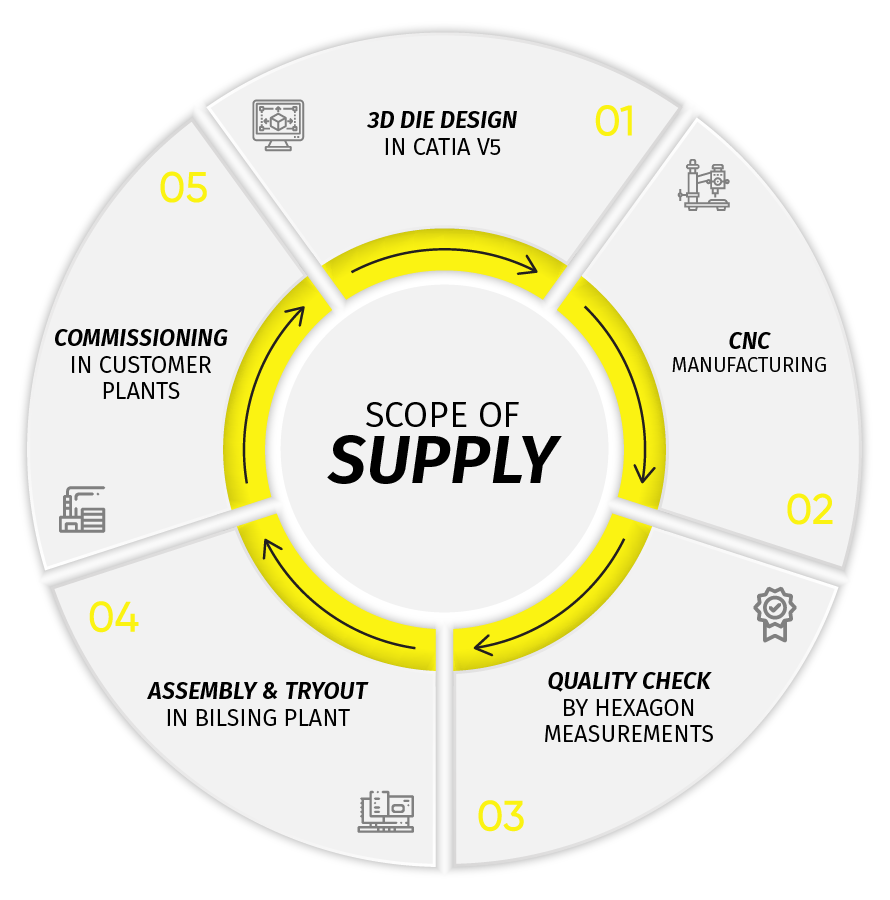

Our dies are made of high-grade tool steel as well as hardened formers, punches and draw rings. Tool production is accomplished exclusively according to CAD constructions and using the latest machining equipment capable of achieving excellent precision and surface quality. By working closely with our engineering team during the design phase, we aim to manufacture economically efficient tools that ensure a competitive advantage for our customers in the marketplace.

On request, we can manufacture prototype tools and individual parts in advance.

At Bilsing Werkzeugbau, our assembly team can handle end-to-end assemblies of the highest complexity, ensuring our tooling produces components of the highest quality. All of our final dies are subject to stringent testing including tryout on our facility test press, ensuring the tooling meets your specifications as well as any required industry standards.